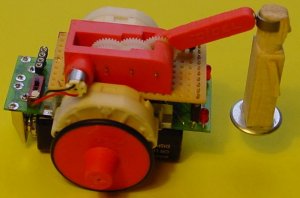

Gears and gear boxes

Miniaturization opens-up a wide set of applications, but many interesting

mechanisms are difficult to miniaturize due to to the difficulty

in getting adequate parts. Small pager motors are available, but

gears, axles, encoders are difficult to get. At LAMI-EPFL, we developed

in 1995-99, thanks to the expertise of André Guignard, small

robots down to 1 cubic centimeter around specially cut gears.

DIDEL sells a proprietary set of Module 0.3 gears (G3xx family),

that still can be implemented with easily available precision machines:

distances between the axle must be met with a precision of 0.02

mm.

|

|